1. Raw material processing

Process the raw materials of self-adhesive paper, including bleaching, impurity removal and other processes to ensure the quality and purity of the raw materials.

2. Pulp preparation

Crush and pulp the processed raw materials, and then mix the pulp with an appropriate amount of additives (such as reinforcing agents, coating agents, etc.) to obtain rubber powder

Pulp.

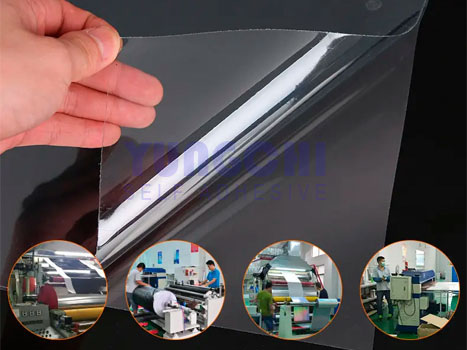

3. Coating

Coat the glue powder slurry evenly on the paper base. You can use a printing machine, coating machine and other equipment for coating. In the coating process, the content of coating agent needs to be controlled

Quantity, speed, temperature and other parameters to ensure the uniformity and quality of coating.

4. Drying

The coated self-adhesive paper needs to be dried. A high-temperature oven or drying tunnel is usually used to heat and dry the paper surface to evaporate the water in the adhesive powder slurry.

The paper surface acquires a certain hardness and strength.

5. Waste gas treatment

A certain amount of waste gas will be generated during the coating process, and the waste gas needs to be treated. Waste gas purification equipment is usually used for dust removal and emission control.

6. Cutting and rolling

The dried self-adhesive paper needs to be cut and rolled. It can be cut into different sizes of paper as needed, and then the roll paper is rolled up.

for subsequent packaging and sales.

The above is a rough self-adhesive paper coating production process. The specific process steps may be adjusted and changed according to the manufacturer and product requirements.

English

English 中文

中文 Français

Français Português

Português اللغة العربية

اللغة العربية

+86-769-88326932

+86-769-88326932