1.Coating Service

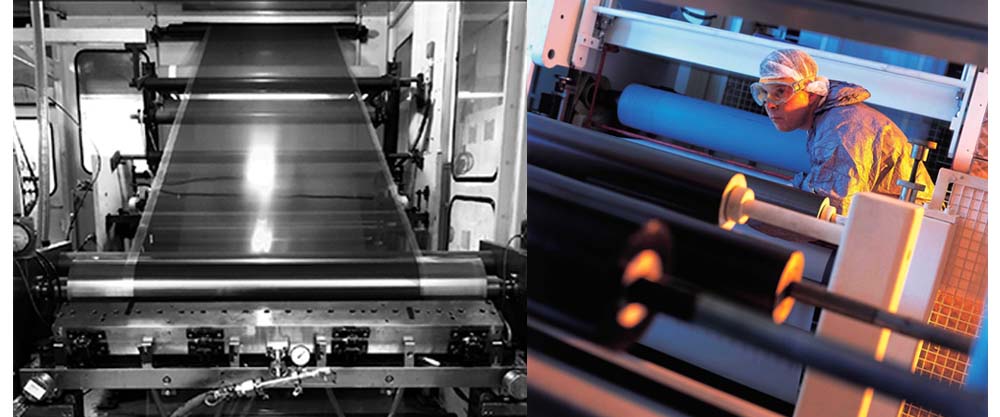

Adhesive Coating

Adhesive coating is a process whereby an adhesive layer is applied to a material. The adhesive is applied to the material using a “dry phase” method to form a single product which has the properties of the combination of the material + adhesive. The primary purpose of adhesive coating is to turn a non-adhesive material into an adhesive material.

Our coating method:

Knife Over Roll Coating utilizes a knife mounted above a roller. The coat weight is determined by the gap between the knife and the roller. The web passes through the gap and the coating is deposited directly onto the web. Knife coating is well suited for fabric and laminate substrates and is often used in trials as the setup is typically simpler than other methods.

2.Converting Services

Rewind Slitting

Winding a large master roll through a series of razor, shear or score blades while rewinding the customized width rolls to a specified length gives a new level of flexibility and efficiency to your engineering and production departments. Extremely narrow or non-standard widths allow your design engineers the freedom not available when working with a small catalog of standard products and sizes. Also, longer machine length pancake rolls reduce downtime in your production process.

Sub-slit materials can be slit into rolls as narrow as 2mm. Lengths and diameters are made to suit post processing needs or final requirements. Slit widths can be held to very tight tolerances +/- .0005. We have laser micrometer with in-line width verification along with additional vision inspection. We also have precision tooling, slitting cartridges, and a high degree of customization.

Custom Sheeting / Winding

All of our products can be slit to your required width. Most material can be offered in Standard Sheet length. Some materials can be supplied in roll form. All products can be delivered with a pressure sensitive adhesive backing.

English

English 中文

中文 Français

Français Português

Português اللغة العربية

اللغة العربية

+86-769-88326932

+86-769-88326932